Specialty Products

Specialty Products

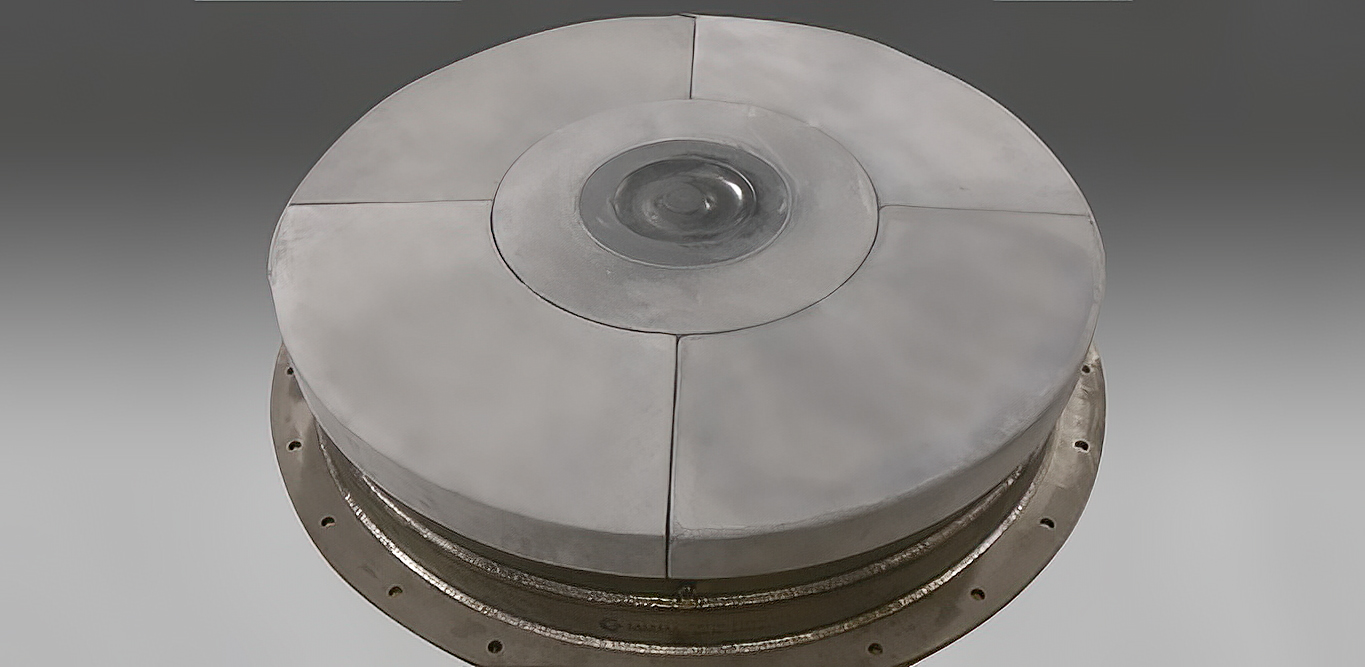

Ceramic Impingement Blocks for Flash Vessel Protection

Flashing slurry letdown systems often require an impingement block to protect the bottom of flash vessels. Impingement blocks are used to deflect high velocity slurry jets that might otherwise penetrate bricking and the metal shell of flash vessels.

Customized Design for Specific Operating Needs

It is critical to engineer impingement blocks correctly to handle process chemistries and high energy slurry flows. Caldera utilizes several design configurations and material combinations in its impingement block designs based on individual customer requirements. Ceramic material options include Nitride Bonded Silicon Carbide, Reaction Bonded Silicon Carbide, and a hybrid Sintered Silicon Carbide / Nitride Bonded Silicon Carbide. The pan / holder can be fabricated from a variety of materials suitable to slurry process conditions.

Caldera has designed and built impingement blocks which include the following diameters:

- 48” (1220 mm)

- 46” (1170mm)

- 36” (915 mm)

- 22.7” (575 mm)

Caldera impingement block ceramics typically range in thickness from 3 to 8 inches (75 to 200 mm) depending on customer requirements. Caldera also provides wall-mounted impingement blocks for slurry jets that enter a flash tank horizontally.

Modular Designs

Caldera’s modular impingement block design allows impingement blocks to be inserted in smaller pieces and assembled within the flash vessel. This design provides greater protection to the flash vessel floor than would typically be possible with smaller blocks limited by the size of vessel access nozzles.

A Note

It is important to understand that an impingement block should be considered a secondary means of protecting flash vessels. The first and most important method of protecting flash vessels is to engineer letdown systems to minimize the energy reaching the bottom of the flash vessel.