About Caldera Engineering

About Caldera

Pressure Oxidation

Overview

Pressure Oxidation (POX) is a process used to extract gold, copper, zinc, molybdenum, and uranium from refractory ore bodies. The POX process utilizes elevated temperatures (roughly 230 degrees Celsius), elevated pressures (roughly 35 bar or 510 psi), and oxygen to liberate the minerals from refractory ores.

POX has been used since 1985 when it was first put into commercial production at Homestake’s McLaughlin mine in California. It has increased in use since that time.

How It Works

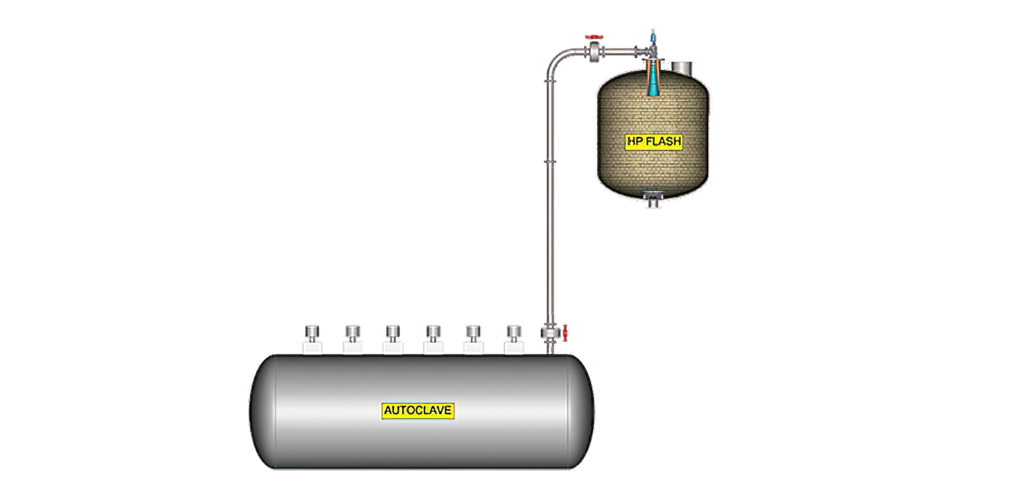

The POX process works as follows: ore is mined and crushed to create a fine material. These fines are mixed with water to create a slurry. This slurry is pumped into an autoclave (a giant pressure cooker of sorts) where oxygen is added. The slurry and oxygen then react as they flow through several compartments within the autoclave. The slurry takes approximately 60 minutes to complete the oxidizing process in the autoclave. Upon leaving the high pressure and temperature atmosphere of the autoclave the slurry must be returned to atmospheric conditions. This is accomplished through one or two letdown/flash stages. Once the slurry is at atmospheric conditions it is washed and separated at which point the gold, copper or other minerals can be recovered from the liquid fraction.

The Benefits

The major benefits of POX are the ability to quickly separate gold, copper, and other minerals from refractory ores, achieve higher recoveries, and reduce environmental impact.

The Challenges

Some of the challenges of POX are:

- Corrosion and Erosion

- Autoclave Level Control

- Operating and Maintenance Procedures

- Plant Availability

If you are designing or operating an HPAL, POX, or other pressure hydrometallurgy plant and have questions about pressure letdown equipment, please call us at +1 801-356-2862.